PhotoScribe Laser Applications

Products from PhotoScribe

LMCP-100 Extreme laser – PhotoScribe Technologies has developed a laser that is the fastest for micro-marking on the pills. The pharmaceutical industry is upbeat about this landmark development as this innovation will boost productivity substantially by reducing expenditure and also a reduction in downtime.

This LMCP-100 Extreme laser developed by PhotoScribe is able to deliver fast, single process and non-contrast marking. Moreover, no consumables are required and thus reducing the cost. The speed of micro-marking is extremely high and huge low in the cost of operation.

LMS-650XS – The latest version of LMS-650XS from PhotoScribe Technologies is the perfect product offering an excellent solution in optical component ID marking for traceability. It is an ideal solution for subsurface and micro-optic marking applications because of its in-built high precision motion system with sub-micron accuracy.

Salient Features and Applications –

- Fiducial Mark- Ideally suited for Optical Marking on components. It can create a fiducial mark and identify the area of transition in optical lenses and eyewear.

- Branding – Marking the brand name on optical components

- Tracking to improve efficiency – Since tracing is significant in sorting and eradicating the defects, efficient unique ID marking becomes that much more essential to track the product through its life cycle. LMS-650XS ID marking lenses the job of ID marking becomes easier and fluid thus helping in productivity.

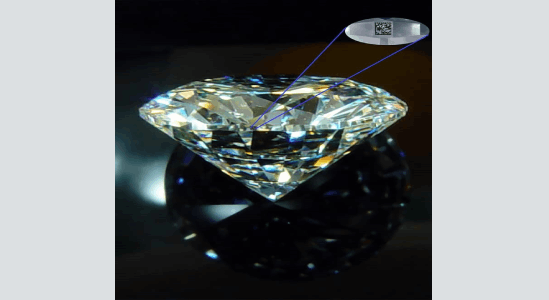

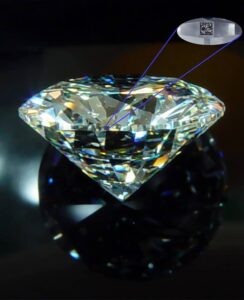

LMS Series – The LMS series from PhotoScribe is very popular for its efficiency in offering the highest precision motion along with pinpoint accuracy. Cold Lasers from the LMS series are ideally designed and created for diamond marking. In using Cold Lasers from the LMS series, there is no complex procedure involved either before or after and the marking process is uncomplicated and simple. This helps to save time and prevent any loss due to damage to the stone.

Process – Cold Laser systems clasp the diamond below a focused beam of ultraviolet light. The light beam extreme focus burns and creates a minuscule pit (~1or 2 microns) on the surface of the diamond. This pit formed will be either transparent or totally black in colour.

Then the characters are marked on the diamond by moving the diamond in the X and Y axis when the laser is firing. It is like writing on paper by moving the paper below a still pencil rather than the usual procedure of using a pencil to write on still paper. LMS Cold Laser System proficiency is well-known for marking on the girdle of the diamond. It can mark the whole of the diamond by enabling a series of rotations.

SurfaceScribe™ markings from PhotoScribe are high-contrast Lasers. They inscribe invisible as well as visible identifiers. These LMS series lasers have various applications. These lasers are used in marking certification numbers in a series, brand names, security marks, photographs, logos, and in many more applications by the top laboratories and major brands.