Iradion Lasers Inc

C. And C. Laser Engineering is the distributor for Iradion Lasers Inc in India.

Iradion Laser is a pioneer among CO2 laser manufacturers. CO2 laser technology of Iradion is the best for laser marking. CO2 lasers give superb results in laser marking and laser engraving under 100watts. Iradion CO2 lasers are suitable for processing various organic materials such as Wood, Paper, Textiles, Plastics, Ceramics, Glass, and Stone.

C. And C. Laser Engineering is a distributor for Iradion Laser in India.

Iradion Laser, Inc is dedicated to developing and creating original, RF excited ceramic core CO2, lasers. This ceramic core technology of Iradion is based on hi-tech technology of aerospace, atmospheric monitoring, military and weapon guidance systems.

This technology is now available for its functioning on a wider scale since it became commercialized a decade ago. In comparison to all-metal lasers existing in the market, Iradion’s ceramic core CO2 laser has a crucial technical edge over other metal lasers in the market, which is significant

Available with powers of 30 to 250 watts, Iradion Laser RF excited CO2 laser has a wider range of applications in the following areas:

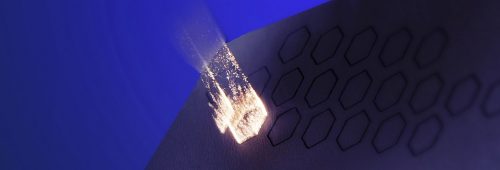

- Laser Marking,

- Laser Cutting,

- Laser Welding,

- Laser Coding,

- Laser Drilling

Industries that are being served by Iradion products are:

- Fashion & Gifts

- Textile & Button

- Automobile

- Pharmaceutical

- Packaging

- Semiconductor

- Medical

Why use a Ceramic CO2 laser tube? What are the benefits of using Ceramic CO2? The simple answer is Ceramic CO2 lasers are reliable and they last long. Thus, saving cost and at the same time providing good quality.

Majority of CO2 lasers available today are based on the method involving extruding or machining aluminium bodies to contain the optical and electrical components inside the laser gas envelope – the laser tube. This approach of developing CO2 lasers was initially developed in the 1970s in various aerospace companies.

However, these designs are ideally suitable for Research and Development work in laboratories, and not specifically suitable for developing highly reliable, long-lasting, durable lasers.

Metal is highly reactive with the gas mixture and this issue thus affects the reliability considerably of metal-tube lasers. Internal components wear and rub against each other and hence fresh aluminium is exposed. Due to oxidation (Oxygen in laser’s gas reacts with this raw material) the composition of the original gas mixture is changed.

Secondly, many of these designs use O-ring seals, which allows the air and moisture to enter and dilute further the efficacy of the gas mixture.

Ceramic CO2 lasers from Iradion eradicate these issues, thus increasing the overall productivity. Ceramic CO2 laser tube technology is a highly effective technology. It eliminates these issues of contamination by shifting all the reactive components to the outside of the laser tube and allowing only pure clean Aluminium (Al2 O3) ceramic to get in contact with reactive gases. Alumina has an inherent chemical property of not reacting with the gas. Alumina can also be fired at an extensively high temperature during the process of cleaning and this feature ensures the removal of all the organic impurities during laser tube manufacturing that can react with the gas.

Some more salient features of Ceramic CO2 laser tube – Iradion’s Ceramic CO2 laser tube is considered the optical backbone holding the resonator optics. Ceramic CO2 laser tube from Iradion has better stability in comparison with metal-based CO2 laser. This is because the coefficient of thermal expansion or CTE of alumina is 1/3 the CTE of aluminium and that is a significant factor as laser tube thermal variations have a direct influence on laser stability. Ceramic CO2 laser tubes enable to use of gas mixtures of comparatively high pressure. This feature of enabling high-pressure gas mixes results in providing faster rise and fall speed and simultaneously much better power stability.