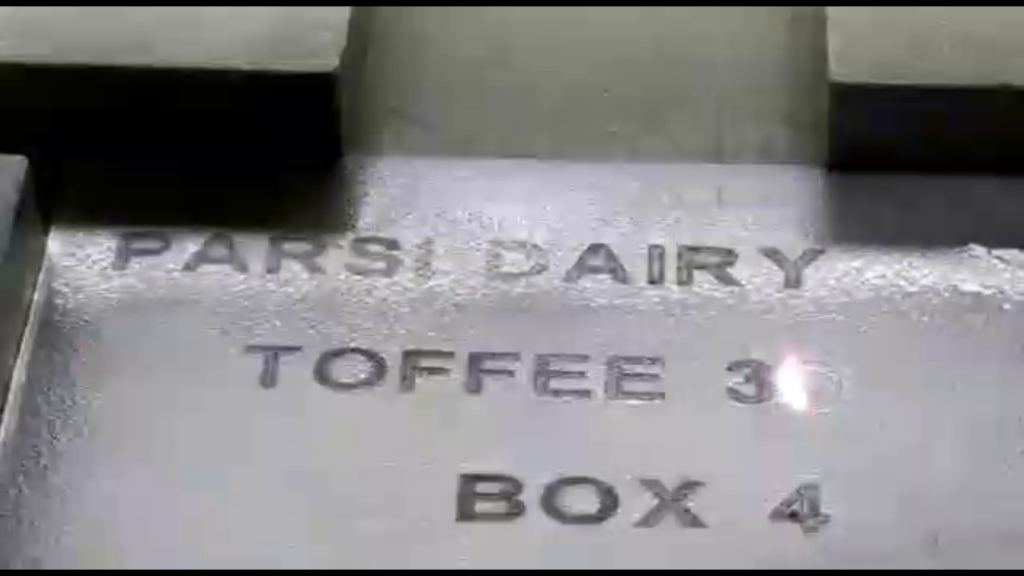

Aluminium Laser Marking

Aluminium Laser Marking:

The video on this page features aluminium laser marking. C. And C. Laser Engineering is popular for its excellent skills in Laser Marking. We provide laser marking of the highest precision across various industrial applications.

In the video on this page Fiber laser marking machine is used for aluminium laser marking. The process is similar to the regular procedure of laser marking with other machines. The Fiber laser beam of 1064 nm is focussed on the target job and then the text and graphics are marked with the focussed beam.

C. And C. Laser Engineering has been regularly providing job works services for laser marking on aluminium, laser marking on glass, laser marking on brass and all types of metals and non-metals and that includes MS, SS, Gold, Silver, Wood, Platinum, Titanium, Tantalum (powder coated, anodized painted or bare), Plastic, etc.

We have excellent proficiency in laser marking, laser welding, laser cutting and micromachining job work services and have executed small-scale projects to voluminous orders for clients based in Mumbai, Pune, Ahmedabad, Bangalore, Surat, Chennai, Delhi and throughout India.

We will be glad to receive your queries, and inquiries regarding laser marking, laser cutting, laser welding and micromachining.

Why Laser Marking?

Laser Marking is permanent and offers the best ROI. It helps improve quality control. Since Laser Marking is permanent and accurate, it is used by manufacturers for tracking the supply chain.

Aluminium has a huge range of applications. Aluminium is used in Industries such as Aeronautics, Automotive, Construction, Defence, Electrical and Electronics, Shipbuilding, Transportation, Household, and Industrial appliances. Since the use of Aluminium across the range of the above-mentioned industries, traceability for tracking the products and their components is very important. Thus, it becomes vital to mark the products with a laser to facilitate easy tracking of the items.

C. And C. Laser Engineering Pvt Ltd. Supplies State of the Art laser marking, engraving, cutting, and micro-machining systems using Fiber Lasers. We understand the actual requirement of the customer and suggest the correct Fiber laser.

Why use Fiber Laser Marking Machine?

Fiber laser marking machines are compact, need negligible maintenance and have no consumable cost. The electrical consumption for a 100W laser is less, as the machine load being is less than 5KVA.

Fiber Laser Marking can be done on a variety of metals. Fiber Lasers can operate at different wavelengths and that is the primary reason for the wide use of Fiber Lasers in industries. Fiber lasers are used in welding, marking, cutting apart from drilling, cleaning, texturing and many more applications.

Fiber Laser is used for the various excellent properties it offers. The speed of Fiber Laser marking is excellent. Fiber Laser Marking is the swiftest in laser marking technology without compromising on quality. It is the ideal combination of speed and quality.

Another significant reason to use Fiber Laser is its durability. The longevity of Fiber Laser is more than other lasers.