Laser Cutting Services

C. and C. Laser Engineering is popular for its efficiency in Laser Cutting and offers the best laser cutting job work services in Mumbai, Pune, Ahmedabad, Surat, Chennai, Bangalore, Delhi, Rajkot, Kolkata and all over India. The clients send us the parts to be cut to our job work centre in Mumbai.

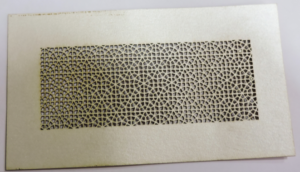

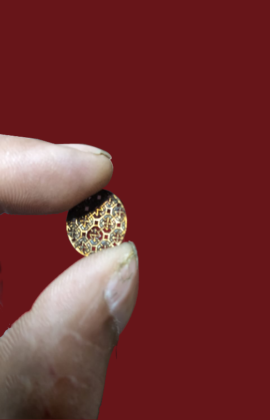

We at C. and C. Laser Engineering have the latest hi-tech laser cutting machines that can cut any metal as well as non-metal. We offer prototype models and have the infrastructure to provide high-volume production runs. We have expertise in laser cutting in jewellery – gold, silver, bronze, brass, paper, card paper, fabric, etc.

C. and C. Laser Engineering offers Fibre laser cutting services and is proficient in laser cutting stainless steel, mild steel, steel sheet, brass, aluminium, etc.

We also offer an exhaustive range of industrial laser products. C. and C. Laser Engineering is also popular for its excellent skills in laser job-work services such as Laser Cutting, Laser Welding, Laser Marking, Laser Engraving, Deep Engraving, and Nanosecond Micro-machining.

What is the Laser Cutting Process? Acronym LASER stands for Light Amplification by Stimulated Emission of Radiation and a Laser beam is highly focussed wavelength radiation that does not scatter or disintegrate. Now in the Laser Cutting process, the laser optics and CNC (Computer Numerical Control) are used to direct the laser beam generated on the object that is to be processed. The beam in the process melts or burns or vaporizes away or is blown away by a jet of gas and then what remains is an edge with a high-quality surface finish as the resultant output.

Why Laser Cutting? There are plentiful reasons to use laser cutting services.

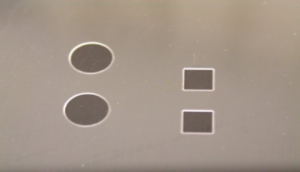

Time-Saving – Laser cutting makes it possible to create small holes as well as complex shapes while cutting and thus there is no requirement for a custom-designed tool. This again helps to save time.

Accuracy – Accuracy is the key factor in job work and in using laser technology you can get the required accuracy even if cut to the minutest geometric shapes and dimensions. Thus laser cutting enables the highest precision even of a minuscule size on a microscopic particle. The process can be set to generate a large volume of production.

No downtime – There is no downtime because using a laser implies no contact during the actual process and thus less chance of repairs and maintenance issues, again boosting productivity.

A laser cutting machine is a perfect solution for cutting because the procedure is non-contact and of high precision due to the use of the laser beam. The process of laser cutting is automated to give the output at high speed even if the quantity is huge, thus giving excellent productivity. Hence it is ideal to use laser cutting to get optimum results.

Applications of Laser Cutting – Laser cutting find its usage in microtechnology and electronics, wherein there is the requirement of the highest accuracy and minimal tolerances. Automotive and Aerospace are other industries that are using this fabulous technology of Laser Cutting to acquire maximum precision while fabricating and manufacturing various spare parts. Since accuracy is its hallmark, Laser Cutting has been instrumental in the creation of highly intricate designs in jewellery, development and manufacturing of highly sophisticated medical devices.

Laser cutting has its applications in various other industries such as Defence, Plumbing, HVAC, Communications – manufacturing mobile phones and other hi-tech communication devices.